One of Hottest for Stamping Automotive Parts - Reinforcement Door Member – Meiln

One of Hottest for Stamping Automotive Parts - Reinforcement Door Member – Meiln Detail:

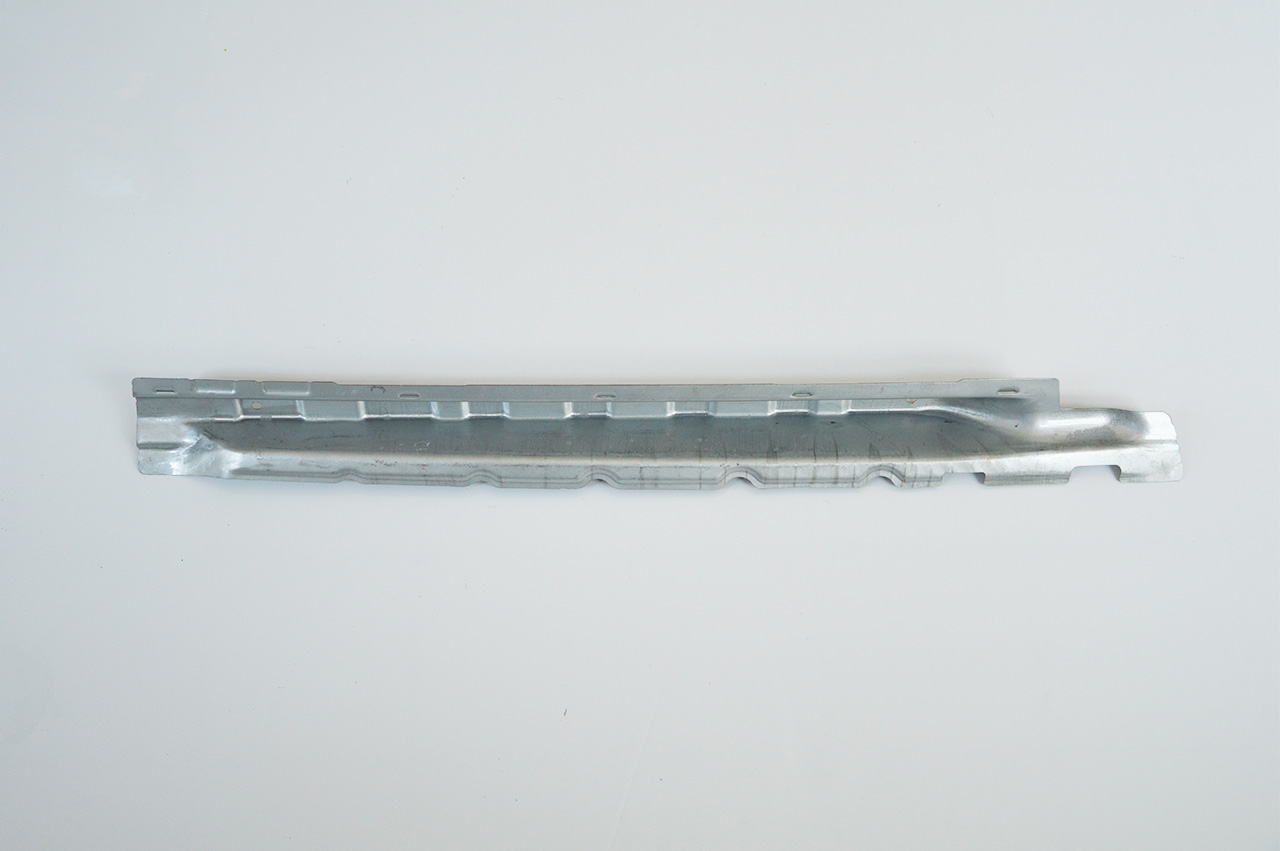

Part Name: REINFORCEMENT DOOR MEMBER

Short/Brief description: Countermeasure to stamping concerns of thin sheet metal part

Material Grade: DX54D+Z140MB0

Material Size: 0.65mm x 940mm x320mm

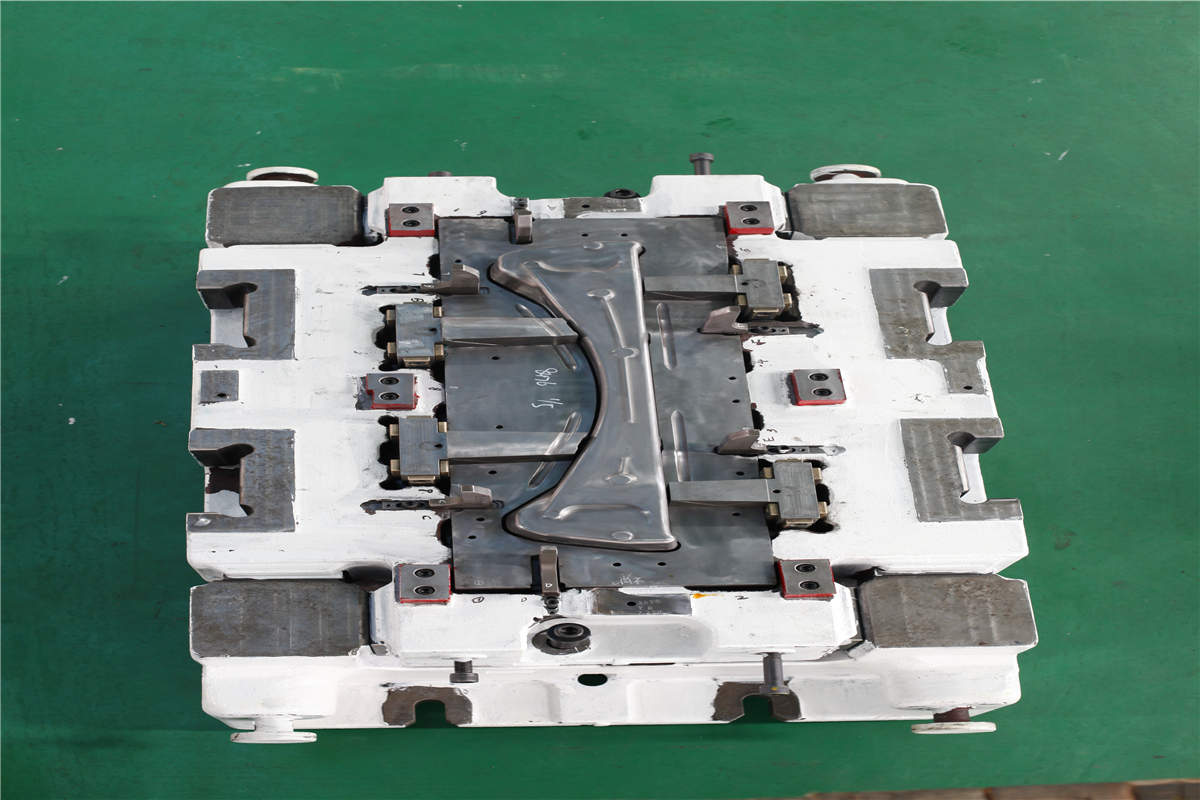

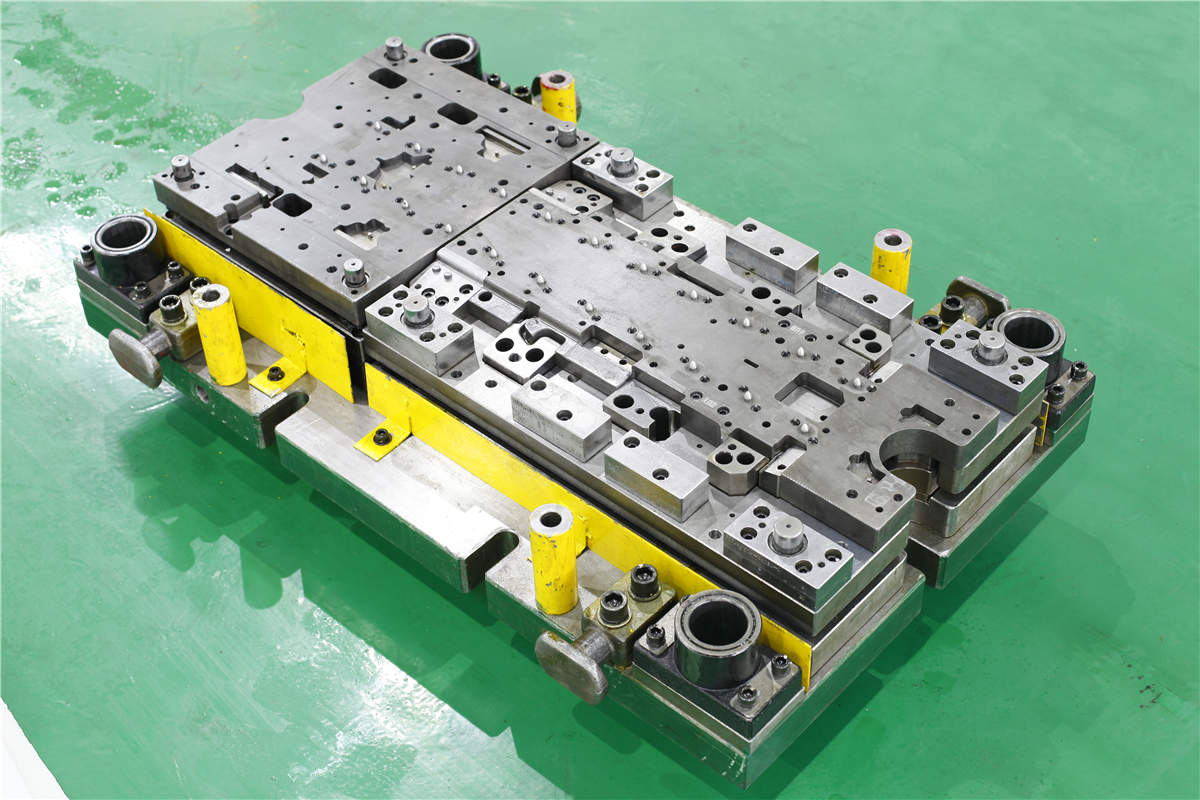

Process: 630T Progression

Cavity: two part out

Complexity: Middle

◆Application: The part applicated to automotive door member part

Press Machine: 2000T hydraulic press, 1200T Mechanical, 630T Mechanical

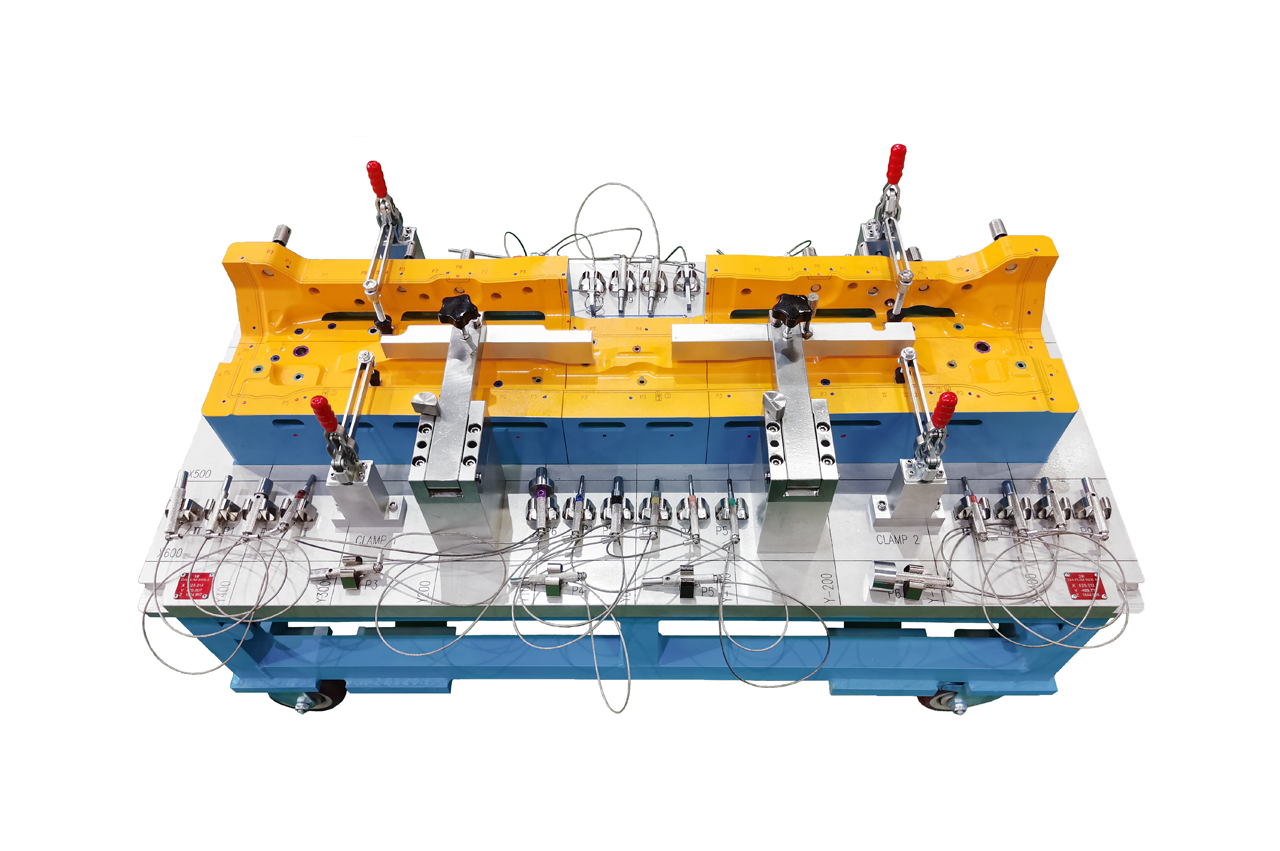

Inspection Tool: Checking fixture, CMM, Laser arm scan

Lead Time: 4 months

◆Part Quality Concern: part potential issues with distortion, wrinkle and burr due to thickness 0.65mm only, so it is very important to pay high attention to die adjust and try out.

Background:

Because material thickness of this part is very thin, which will easily cause part quality with distortion, wrinkle and burr issues. Besides, it is not easy to adjust the die cut clearance that caused in burr, also high requirement for die spotting, otherwise will not form in place, as well as part is unstable and will affect the flatness during stamping.

Concern over part distortion and burr, as we know, slight distortion will affect part appearance, and serious distortion will directly affect part assembly and fitment. Due to this, we adjust die cut clearance, die surface flatness and the die spotting to improve distortion. The countermeasure to solve the burr is that first must ensure the processing accuracy and assembly quality of punch and die button, as well as die strength, second ensure the correct clearance of punch and die button. By these way, final part quality is better than the first try out part which shown no burr, distortion and wrinkle.

Conclusion:

As we known that distortion, wrinkle and burr, ect. are common issues for stamping part, in order to ensure the part quality, our engineers and technicist will make a case-by-case analysis and make a correct countermeasure to solve such common problem.

If you want to know more countermeasure with such thin sheet metal part or have other questions, please don’t hesitate to contact us, and we will be pleased to reply and discuss with you.

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for One of Hottest for Stamping Automotive Parts - Reinforcement Door Member – Meiln , The product will supply to all over the world, such as: Ghana, Lesotho, Rotterdam, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.