OEM China Metal Work Measuring Tools - progressive tool – Meiln

OEM China Metal Work Measuring Tools - progressive tool – Meiln Detail:

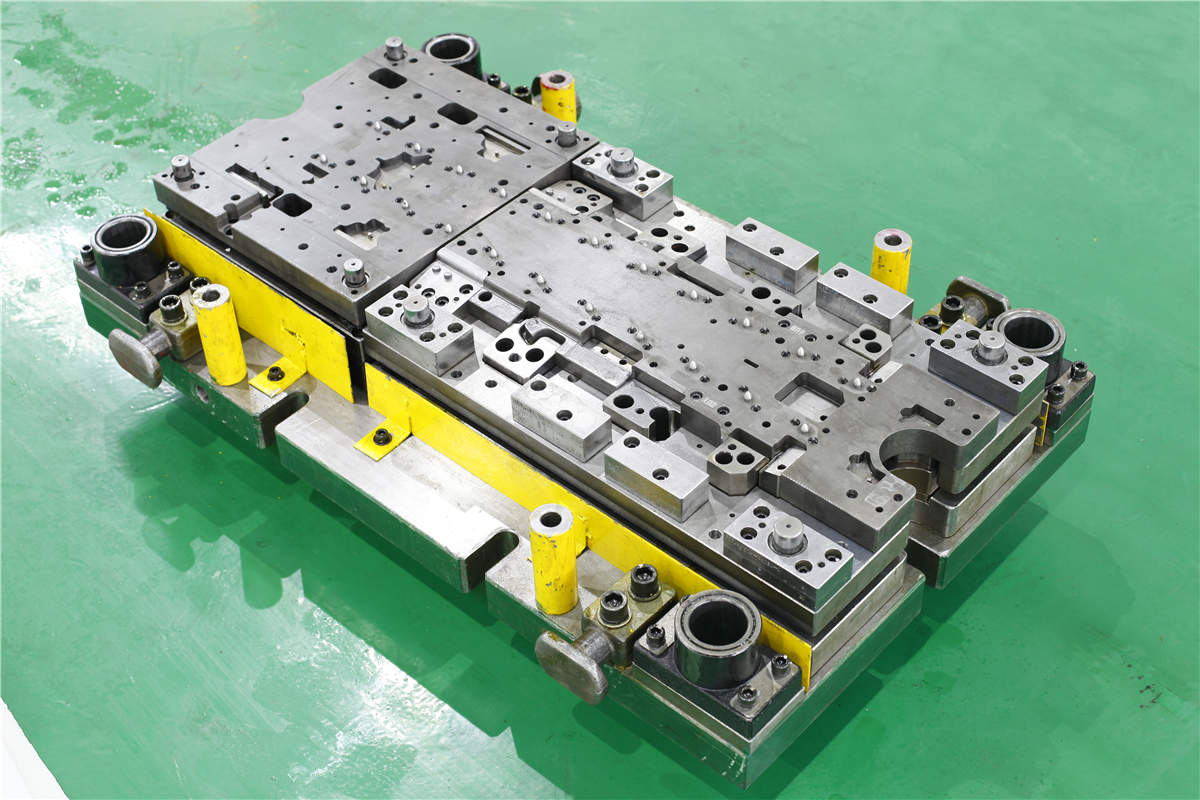

Tool type: Progressive tool

Process:

1.60mm x 158mm x 106mm – 250T PRG @ x2 Part Out

1.60mm x 371mm x 67mm – 500T PRG @ R/L Parts Out

1.40mm x 260mm x 221mm – 600T PRG @ x2 Part Out

Stamping Part Material: SCGA270D-45/SCGA590DU-45/SCGA270D-45

Tool Material Grade:

Upper and Lower die shoe & blank holder are used S50C material,

Forming and re-strike blank holder plates are used HMD5 material,

trim punch blank holder plates are used S50C material.

Steel Surface Treatment:

Forming punch: PVD

Forming punch:SKD11+TD

Standard Components:

Most of standard parts are sourced from MISUMI and PUNCH, gas spring are sourced from HYSON.

Complexity: Easy

◆Application: The tool applicated to automotive stamping part mass production.

Lead Time: 2.5~3 months

Background:

In the stamping production of progressive stamping die, it is necessary to carry out specific analysis

for the phenomenon of poor stamping, adopt effective treatment measures, and fundamentally solve

the problems that occur, so as to reduce production costs and achieve smooth production. The

following is the reason for the common bad stamping phenomenon in production and the treatment

measures are as follows, for the tool maintenance personnel to refer to.

The progressive stamping punching edge

Cause:

1) The cutting edge wear,

2) The gap is too large to repair the cutting edge after the effect is not obvious,

3) The cutting edge collapse angle,

4) The gap is unreasonable up and down offset or loose, Up and down dislocation.

Countermeasure:

a. Grinding the cutting edge,

b. Control the precision of the convex and concave die machining or modify the design gap,

c. Grind the cutting edge,

d. Adjust the punching clearance to confirm the problem of the hole wear of the template hole or the processing precision of the molded part,

e. Replace the guide or Remodeling.

If you are interested in progression tool or have any other questions, please don’t hesitate to contact me, and we will be pleased to reply you.

Product detail pictures:

.png)

.png)

.png)

-12190(170)(合模).png)

-12190(170)(上模).png)

-12190(170)(下模).png)

.png)

.png)

.png)

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for OEM China Metal Work Measuring Tools - progressive tool – Meiln , The product will supply to all over the world, such as: Indonesia, Guatemala, Colombia, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.