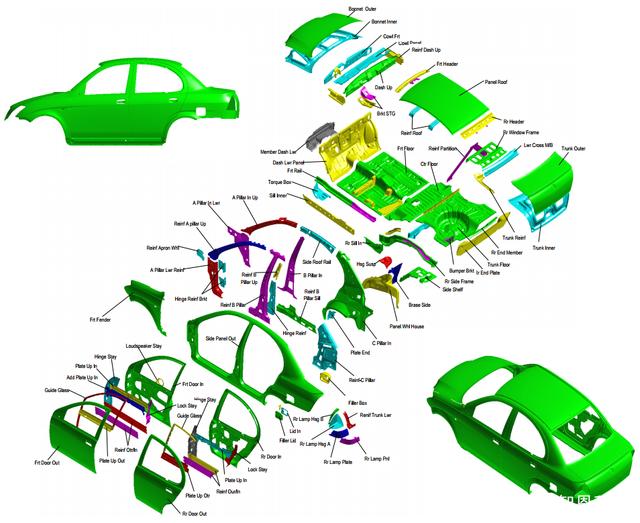

Automobile covering parts (referred to as covering parts) refer to the surface parts and internal parts of the thin steel sheet expansion body that covers the engine, chassis, cab and body. Compared with general stamping parts, covering parts have the characteristics of thin material, complex shape, space curved surface, large structure size and high surface quality.

The characteristics of automobile covering parts as below:

(1) pressure parts, such as the side parts of some models of domestic cars, the length size can reach more than 3000mm, the shape is complex. (2) The outer and inner covering parts are made of 08AL or ST14 materials with a thickness of 0.75mm, 0.8mm, 0.9mm, 1.0mm, 1.4mm, etc., and are made of CR4 or JAC340H steel plate with a thickness of 0.60mm, 0.65mm, 0.70mm, 0.75mm, 1.2mm, etc. In India, 0.67mm thick sheet with material code C23 is also used. Now some car interior covering parts, such as left/right front door inner panel, left/right rear door inner panel, are made of two kinds of thickness materials (generally 0.8mm and 1.4mm), using laser welding and other processes (or welded plate), its purpose is to improve its strength, to avoid the deformation caused by frequent opening and closing of the door. (3) Most covering parts generally have to go through the drawing process to get. (4) The deformation process of the material is complex during stamping forming. Professional software, such as AutoForm, must be used to analyze and simulate whether the local quality defects such as tensile cracking phenomenon may occur in the drawing deformation process. (5) Must use the equipment (such as coordinate measuring instrument, etc.) and special quantity, to evaluate its size and shape is qualified. The tonnage of the punching equipment used in processing is generally relatively large, the largest press can reach more than 2400t.

Post time: Apr-19-2023