New Fashion Design for Precision Stamping Parts - Reinforcement C Pillar Outer – Meiln

New Fashion Design for Precision Stamping Parts - Reinforcement C Pillar Outer – Meiln Detail:

Part Name: Reinforcement C Pillar Outer

Short/Brief description

C pillar part with draw process issues

Material Grade: MJSC270D-OD

Material Size: 1.40mm x 1300mm x 605mm

Process: 800T Progression Blank & x4 Stage 3000T TRF

Cavity: R and L two part out

Complexity: Middle

◆Application: The part applicated to automotive C pillar outer part

Press Machine: 2000T hydraulic press, 1200T Mechanical

Inspection Tool: Checking fixture, CMM, Laser arm scan

Lead Time: 4 months

◆Part Quality Concern: As car cover part, when C pillar part in the drawing process, the uneven flow of blank caused by drawing bead arrangement is one of the important reasons for wrinkle and split issues.

Process Background:

According to the forming characteristics of the cover part, the basic shape of C-pillar reinforcement must be completed in one drawing procedure. When the body in white is welded, the pressing surface on both sides of the part should be matched with the C pillar and should be flanged. After process analysis, the preliminary determination of the parts using 4 processes forming, first drawing, then trim-pierce, flanging-restrike, at last trim-cam/pierce -pierce.

In order to improve wrinkle and split issues, when part in the draw process, some methods can be used to control the flow of the material, so that the deformation is as regular as possible, such as process supplement, blank holder surface or draw bead, which can ensure the stability of the parts. For this part, we think it is necessary to set the drawing bead on the blank holder surface, which can control the material deformation size and grain flow.

Conclusion:

Through the process analysis of C pillar outer plate parts, which is s a reference for the stamping process analysis of similar parts and other parts. In the future practice, we hope to research the automotive stamping parts of the process in-depth.

If you want to know more about auto cover parts, such as A/B/C pillar reinforcement parts, please don’t hesitate to contact me, and we will be pleased to discuss with you.

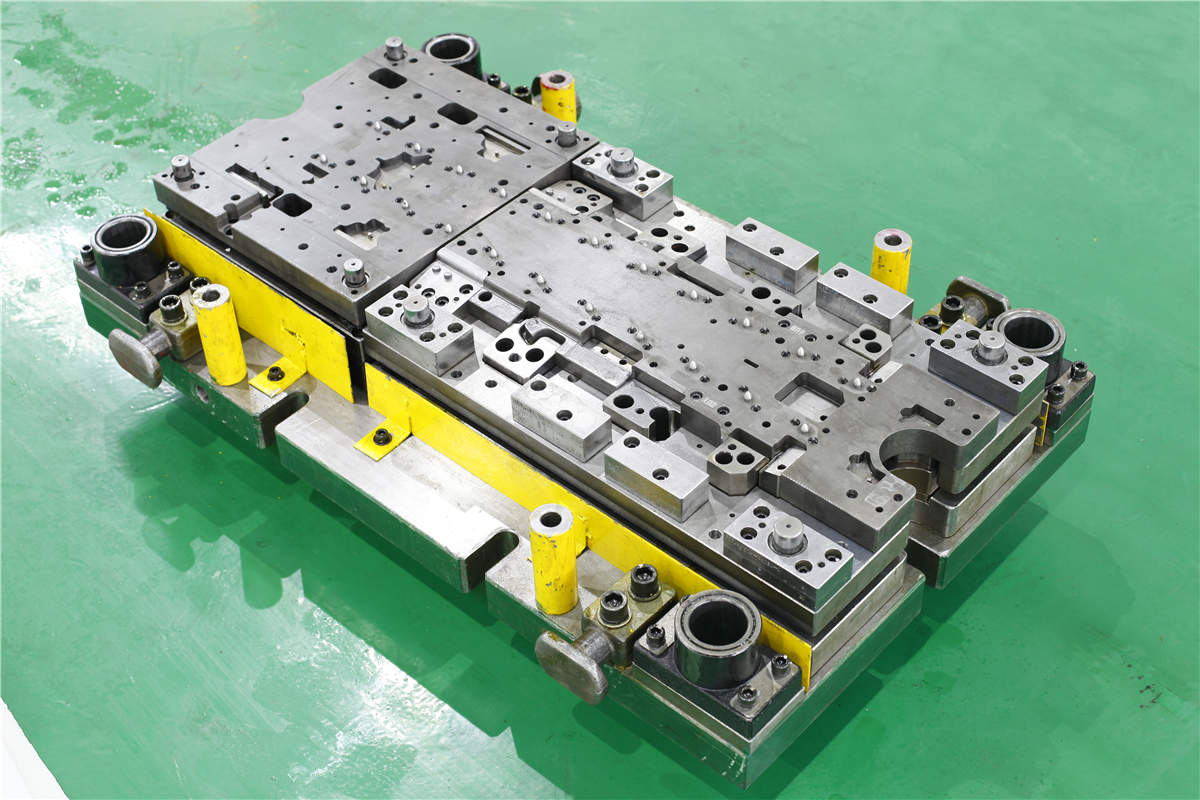

Product detail pictures:

Related Product Guide:

owing to fantastic assistance, a variety of high quality goods, aggressive rates and efficient delivery, we love a very good popularity among our customers. We are an energetic firm with wide market for New Fashion Design for Precision Stamping Parts - Reinforcement C Pillar Outer – Meiln , The product will supply to all over the world, such as: Plymouth, Malta, Manchester, All the employees in factory, store, and office are struggling for one common goal to provide better quality and service. Real business is to get win-win situation. We would like to provide more support for customers. Welcome all nice buyers to communicate details of our products with us!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.