Factory selling Checking Fixture For Automotive Bracket - Fixture resin – Meiln

Factory selling Checking Fixture For Automotive Bracket - Fixture resin – Meiln Detail:

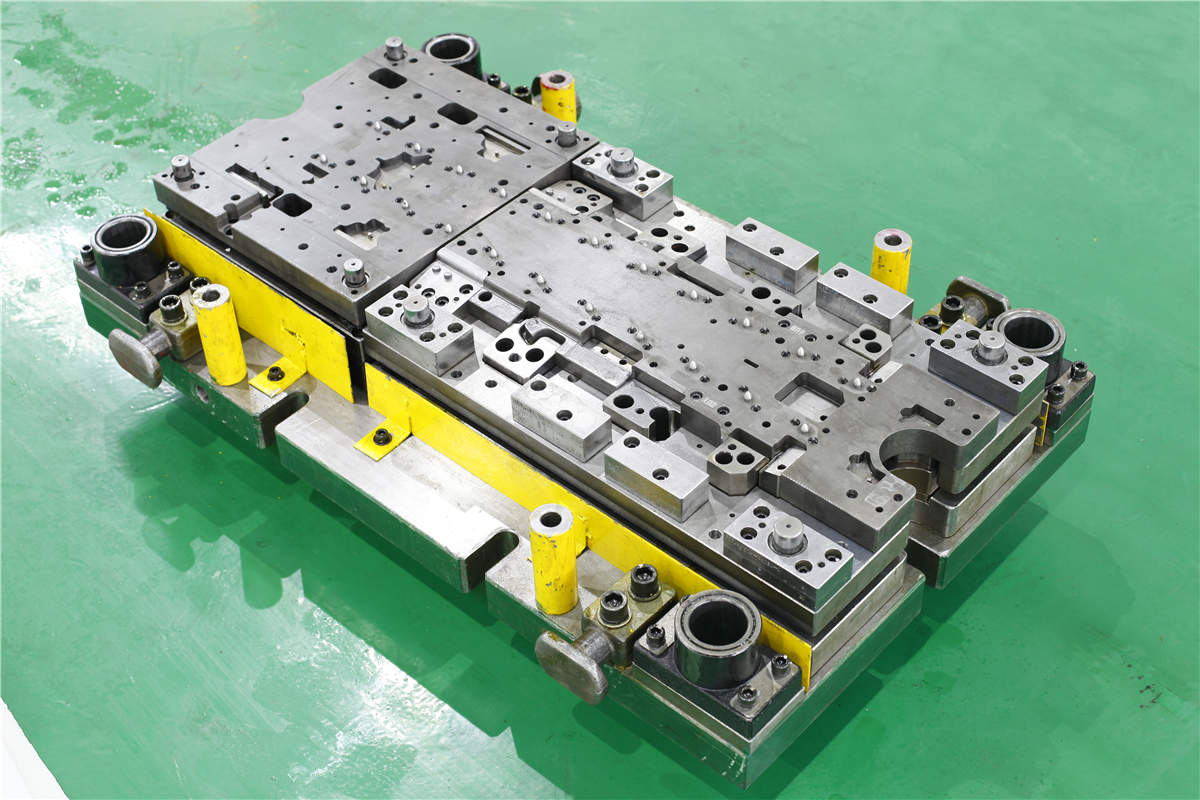

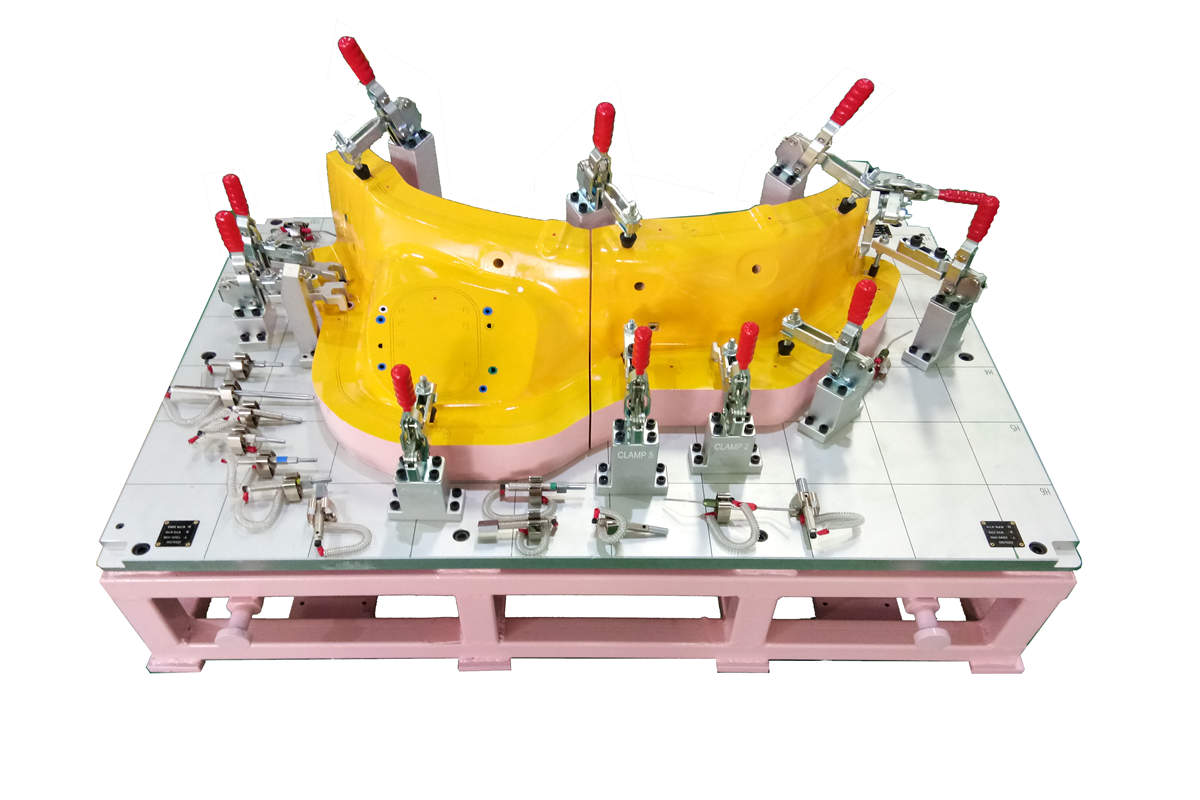

Part Name: ZB GEPAECKRAUMWANNE MITTE

Cavity: one part out

Material: Base Plate is made of Aluminum and Main body is made of Resin

Treatment: Metal area =Anodised

Resin area =painted

Lifting Method of Fixture: trolley

Application: The fixture applicated to automotive stamping part measurement

Lead Time: one month

Background

Regarding the lifting method of fixture, we consider all fixtures require an easy method of lifting, whether this by hand and adding handles or for larger fixtures ensuring that they are on a trolley to ensure easy movement. Some fixtures which are overweight and due to the size they can’t be manually lifted. These items require lifting aids to be added to make users friendly.

As to fixture material, this fixture is made of resin, which is not easy to deform even under the influence of environment, and is conducive to dimensional stability.

There are three alignment plates sat on fixture corners, which have come in with correct ‘X,Y,Z’ co-ordinates making it easy to accurately measure the part in car line. These plates are meant to be the datum of the fixture, these being correct means correct measurements could be sent to customer.

Function of the fixture

1. Inspect the hole position and hole size tolerance of the part.

2. Inspect the relating surface profile of the part.

3. Inspect the relating trim of the part.

4. Inspect the other relating dimensions of the part.

Fixture Maintenance

1. Apply for anti-rusty oil on the locating pins after using each time

2. Put the gauge in a specified area and cover the dust cover.

3. Not allowed for any heavy things to hit or touch or extrusion. Otherwise, the gauge precision will be affected.

4. Not allowed to disassemble the gauge. Otherwise, will be badly affected with the gauge precision.

If you have interest or want to know more about Resin checking fixture, please do not hesitate to contact us. We are pleased to discuss with you.

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Factory selling Checking Fixture For Automotive Bracket - Fixture resin – Meiln , The product will supply to all over the world, such as: Pakistan, Uruguay, The Swiss, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.