Factory Price Auto Stamping Parts - Automotive BRACE-SILL Product – Meiln

Factory Price Auto Stamping Parts - Automotive BRACE-SILL Product – Meiln Detail:

Brief Description: High tensile strength part deforming and twist concerns

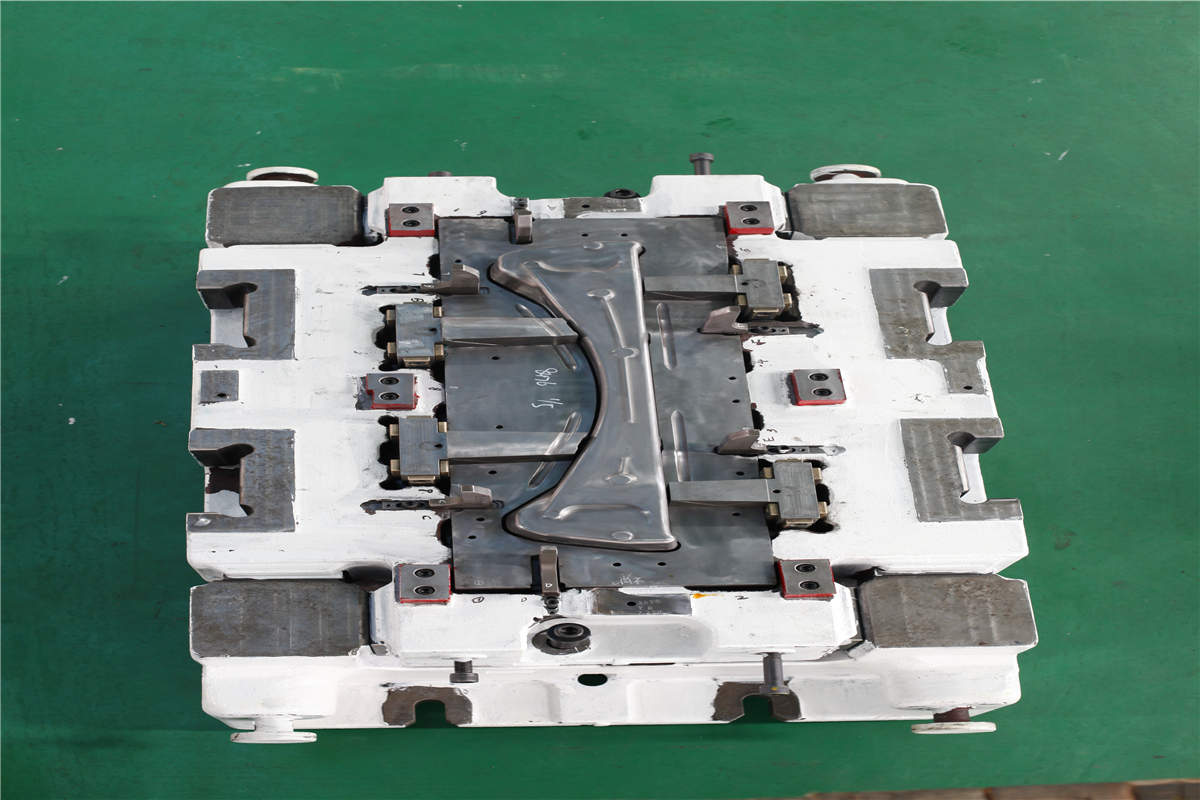

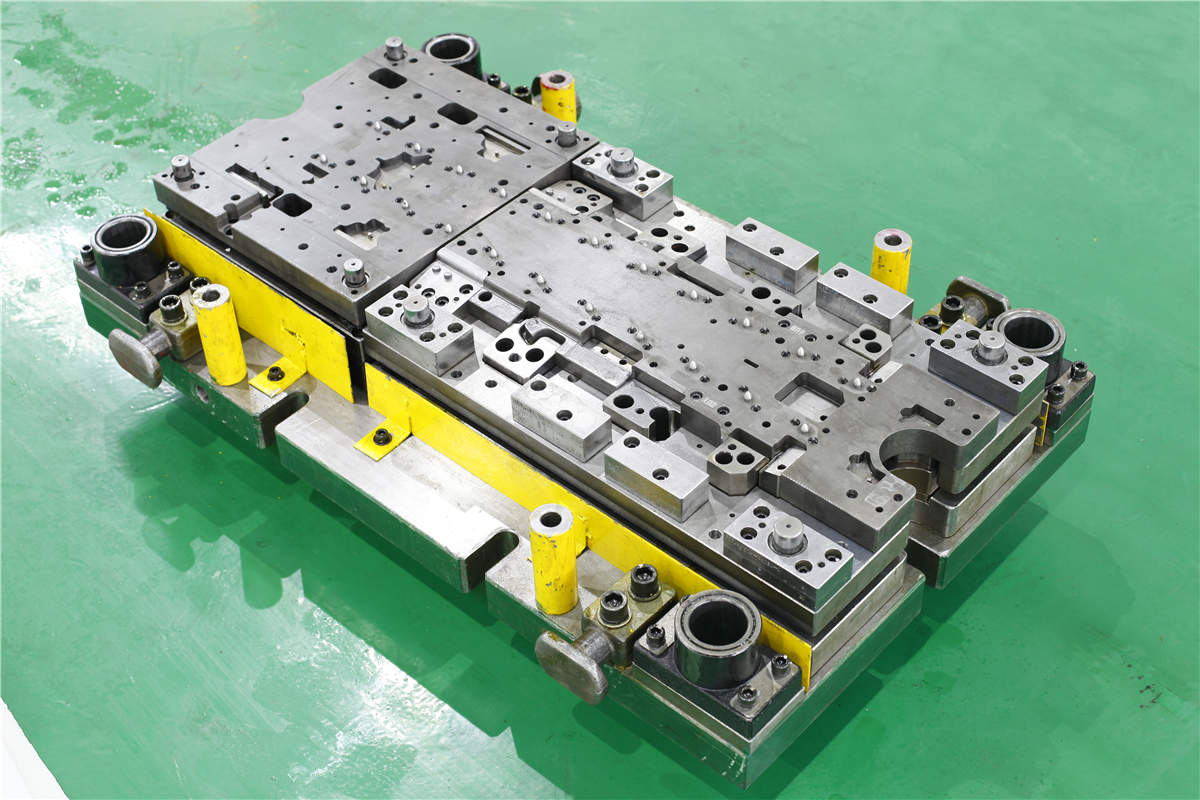

Part Name: Automotive BRACE-SILL Product

Material Grade: Material RP783-780

Material Size: Material size is 1.6mm x 1400mm x 445mm

Process: Process 1000T progressive blanking and 3000T transfer 3 stages

Cavity: Tool cavity is right and left two parts out

Press Machine: 1200T Mechanical

Inspection Tool: Checking fixture, Blue scanner

Lead Time: 4 months

Key and difficult point summary:

Product high quality control and management

Deforming and twist during forming;

As part big size, and high strength material common concern- deforming, head and tail twist. On the condition that to keep accuracy of the holes, how to improve deforming and twist concern is a critical task. Our technical team hold the discussion meeting, review the original forming simulation, fully overview and compare the deforming. The simulation showed good result, no such bad twist condition, just several points on the surface over the limit. The solution is to find the key area, no beads, no ribs, no feature design change. Blue lead tested again, even to scan the forming steels. Combined all above methods, part twist to be solved.

Surface gap tolerance ±0.3mm;

The product in special characteristics and key features, the surface gap requested to be ±0.3mm, all surface measurement points including datum. Most of the checking points are OK to achieve, however, any slightly change of the die could cause the surface out of the tolerance. 95% quality at T3 level, while meet 100% cost a little more time to modify the surface.

Trim tolerance ±0.5mm;

Besides the surface gap special tolerance, also trim still requested to keep in ±0.5mm, some areas in wave shape, any forming error, tolerance for surface and trim are changed accordingly.

In order to keep hole, surface and trim all checking points quality, all have to be solved at the same time.

Do please contact with us if you have interest in handling the deforming and twist for high strength steel material for big size like this slim product.

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products and solutions into the market each year for Factory Price Auto Stamping Parts - Automotive BRACE-SILL Product – Meiln , The product will supply to all over the world, such as: Libya, Estonia, Gabon, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a personalized tour and advanced business guidance.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.